Sublimation Products

How to Print Files for Sublimation Products[edit]

Printing to this machine is unlike any other printer we use. It's very manual and most things like color management, sharpening, crop marks, etc. would normally be handled via the workflow/RIP have to be done in Photoshop when printing to this device. When producing most products you'll have to flip the image. The exception would be something like a glass ornament since it's transparent and the finished side is the shiny side and not the sublimation side. Also you'll need to slightly oversharpen when printing these files due to the nature of essentially melting the image onto the sublimation surface. You may also want to print with crop marks. See below for sharpening instructions and color management settings.

Sharpening

1) Once you make any enhancements to the file you'll need to flatten, then mirror flip the image.

2) Make an a copy of the background layer.

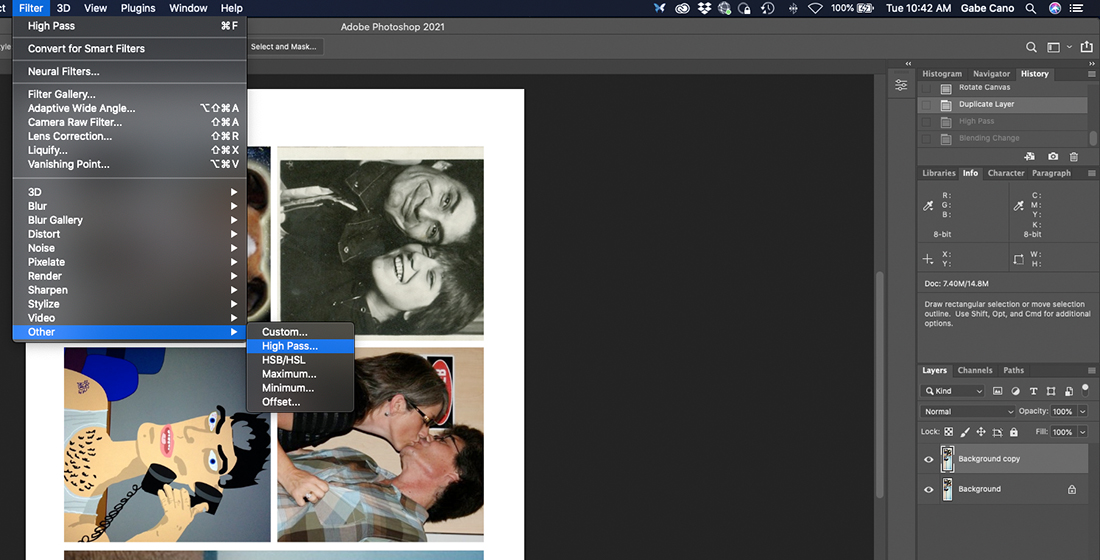

3) With the newly created "Background Copy" layer selected, go to Filter>Other>High Pass

4) Set the Radius to 1.8 Pixels. Click OK.

5) On that layer, you'll now want to set the layer mode to "Overlay"

6) Flatten image.

7) The file is now sharpened and ready to print.

Print Settings

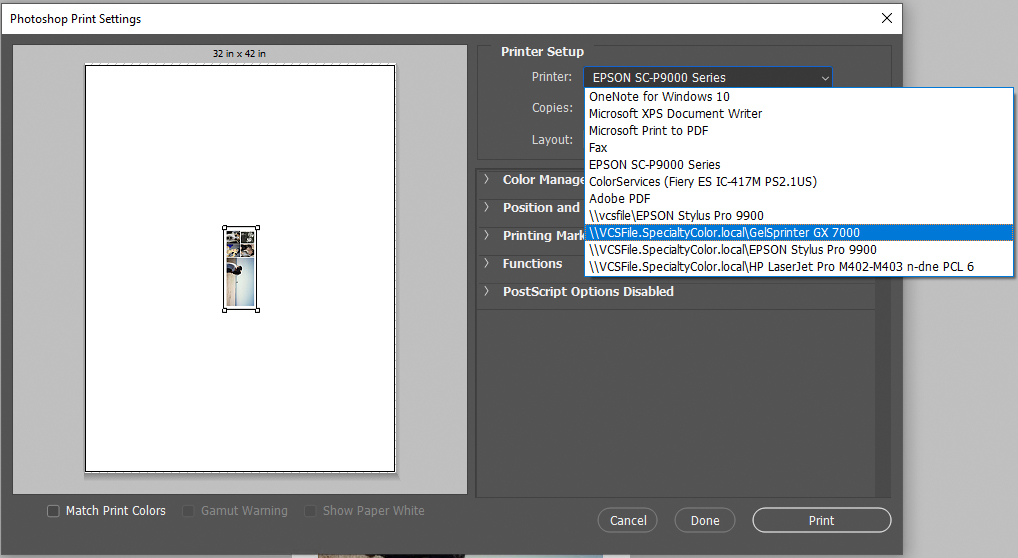

1) Go to print and then select the GX7000 Printer.

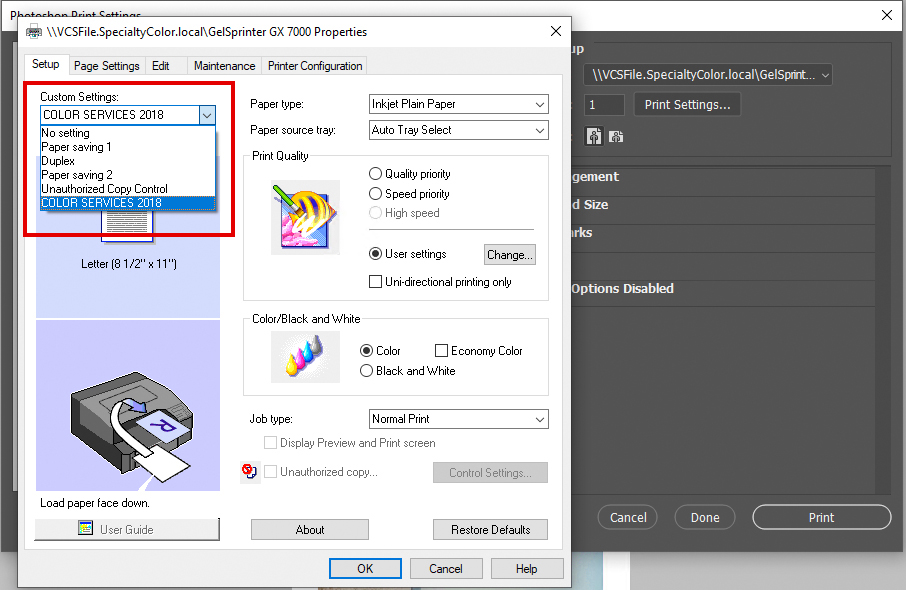

2) Now click on printer settings. That will open up the print settings for the Ricoh. Select the Custom Settings "Color Services 2018" and hit OK.

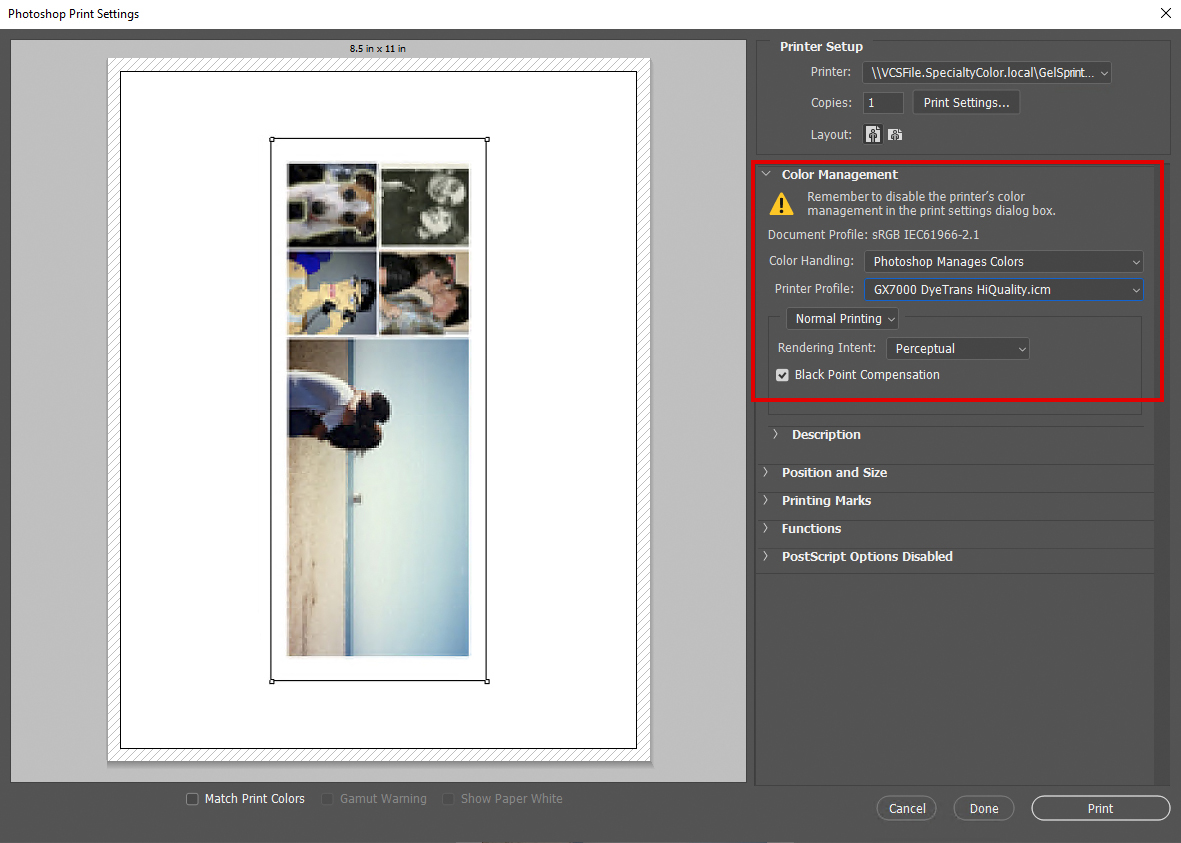

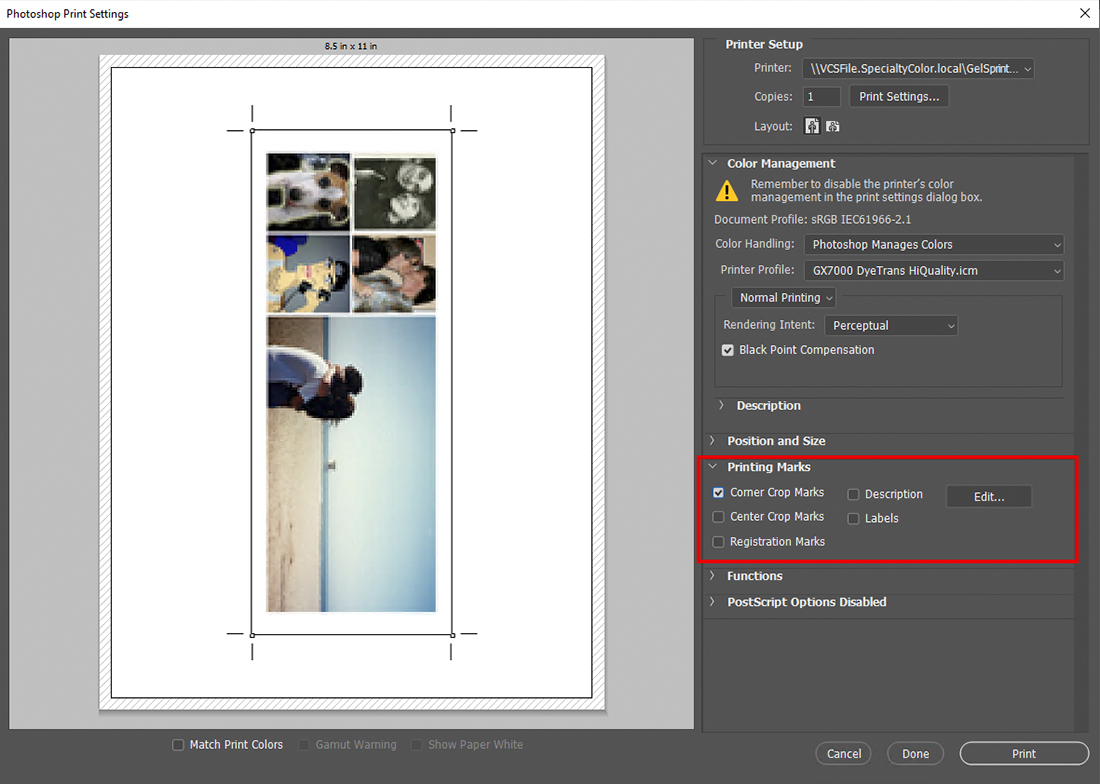

3) Now copy the color settings into the Photoshop Print Dialogue. See Below.

4) Turn on corner crop marks if needed.

5) Print.

Instructions for Sublimating onto the Physical Products[edit]

Ceramic Mugs - Made in USA Style

400 degrees, 5 Minutes 30 Seconds

Use Dk3 Mug Press. Before Warming up press make sure the pressure around the mug is sufficient. Use clean piece of paper around the outside of the mug when pressing to protect green pad from getting stained. In the order goes; Mug, Transfer paper facing in(use heat tape to secure onto mug), and White paper.

Stainless Steel Travel Mugs

400 degrees, 1 Minute 30 Seconds

Before Warming up press make sure the pressure around the mug is sufficient. Use clean piece of paper around the outside of the mug when pressing to protect green pad from getting stained. *This mug is very tricky to make. It takes quite a nit of effort to adjust the press to open large enough to accept this large of a diameter. What does help is enlarging it as much as possible, open and closing it several time and then repeating that when you contract the press as much as possible as well. In order goes; Mug, Transfer paper facing in(use heat tape to secure onto mug), and White paper.

Stainless Steel Water Bottles

400 degrees, 6 Minutes

Before Warming up press make sure the pressure around the mug is sufficient. Use clean piece of paper around the outside of the mug when pressing to protect green pad from getting stained. *This product requires a small piece of green pad. Put that around the white cover sheet of paper. In order goes; Water bottle, Transfer paper, White Paper, and Greed Pad. Template dimension should be 8.16" x 4.45" at 300ppi.

Ceramic Magnets

400 degrees, 7 Minutes

magnets need lots of pressure. Make sure to test the pressure before you start to hear up the press. Transfer paper up, magnets face down. Use white cover paper below transfer paper and on top of the ceramic tiles. Use green pad on top of the second piece of paper. In order goes; White Felt, White paper, Transfer paper face up, Ceramic tiles face down, White paper, Green pad.

Photo Coasters

400 degrees, 4 Minutes

Use White Felt underneath, white paper, then tile face up, transfer paper, white paper and then finally 1/8” green pad on top.

Easel Back Metal Prints & Phone Cases

400 degrees, 1 Minute 15 Seconds

IMPORTANT: Metal comes with a plastic covering on transfer side. MAKE SURE TO PEEL THAT AWAY BEFORE PRESSING! Use clean piece of paper above and below to protect black pad and underside of press. In order goes; White paper, Transfer paper face up, Metal Face down, white paper.

Metal Ornaments

400 degrees, 1 Minute 15 Seconds

Press both sides at once. Use clean piece of paper above and below to protect black pad and underside of press.

Glass Ornaments

400 degrees, 5 Minutes - Medium Pressure

Press face down and use green pad on top.

Porcelain Ornaments

400 degrees, 2 Minutes 45 Seconds

Use Nomex Felt above and below transfer paper. (White felt) In order goes; Felt(1x), White paper(2x), Transfer paper, White paper(2x), Felt again(3x). Achieve this by folding felt twice. One side at a time, use tape first side and none second side.

Mouse Pads

400 degrees, 1 Minute 30 Seconds

Transfer paper facing down, mouse pad facing up, use heat tape. In order goes; White paper, Mouse Pad facing up, Transfer paper facing down, White paper.

Wood Ornaments

400°F, 35 - 40 seconds

Pressure Light

1) Lay down protective paper on the heat press platen.

2) Lay down your panel image side face up and use Pro Spray to attach the transfer.

3) Cover with another sheet of protective paper and press.

4) After removing from the press, immediately turn over the ornament and cool under a heavy weight to minimize warping.

ORDER GOES --

white paper, wood ornament, transfer image face down, white paper

Contemporary Water Bottle

Medium to Heavy Pressure

1) Remove lid

2) Heat tape transfer to bottle

3) This product requires a small piece of green pad. Put that around the white cover sheet of paper. In order goes; Water bottle, Transfer paper, White Paper, and Greed Pad.

4) Time - 2 minutes 30 seconds